Metal Widebelt EZ Sanders

Deburring, Grinding, Slag/Dross Removal, Straight Grain Finishing

The Metalworking Widebelt EZ Sander is a cost-effective way to finally upgrade your deburring and finishing operations, moving away from time-consuming hand grinding. With just a quick change of the abrasive belt, this compact machine can remove slag/dross, grind vertical burrs, or straight grain finishing (including some mill scale removal).

The EZ Sander was developed to fit the needs of both small metalworking shops, as well as, large production facilities looking for an easy way to run small projects “off-line” from their main production flow. With a small footprint and the ability to mount on casters, this machine is portable enough to fit almost any shop. Don’t let the small size fool you, the EZ Sander is loaded with features and is heavy-duty enough to provide years of dependable, consistent, labor saving production.

EZ SANDER MACHINE FEATURES

- 36″ wide part capacity

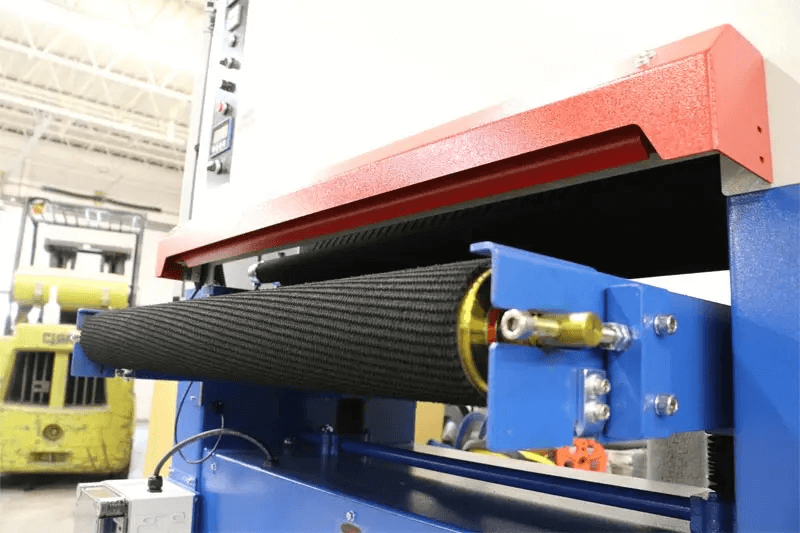

- 37″ x 60″ abrasive belts

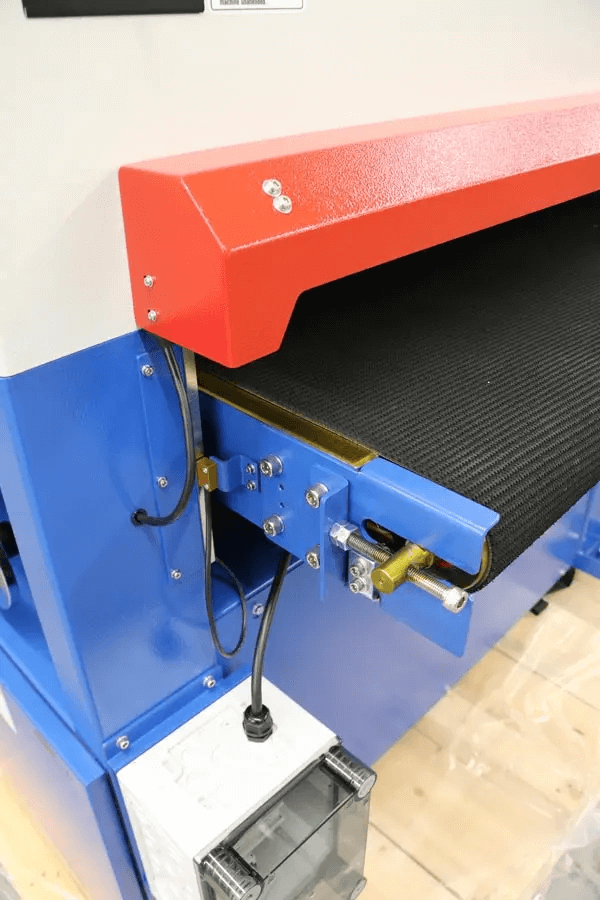

- Variable speed conveyor at 5-25 fpm

- 5″ bed opening with motorized lift

- Digital thickness readout for conveyor height

- Control panel with motor load meter, hour meter, and digital readout

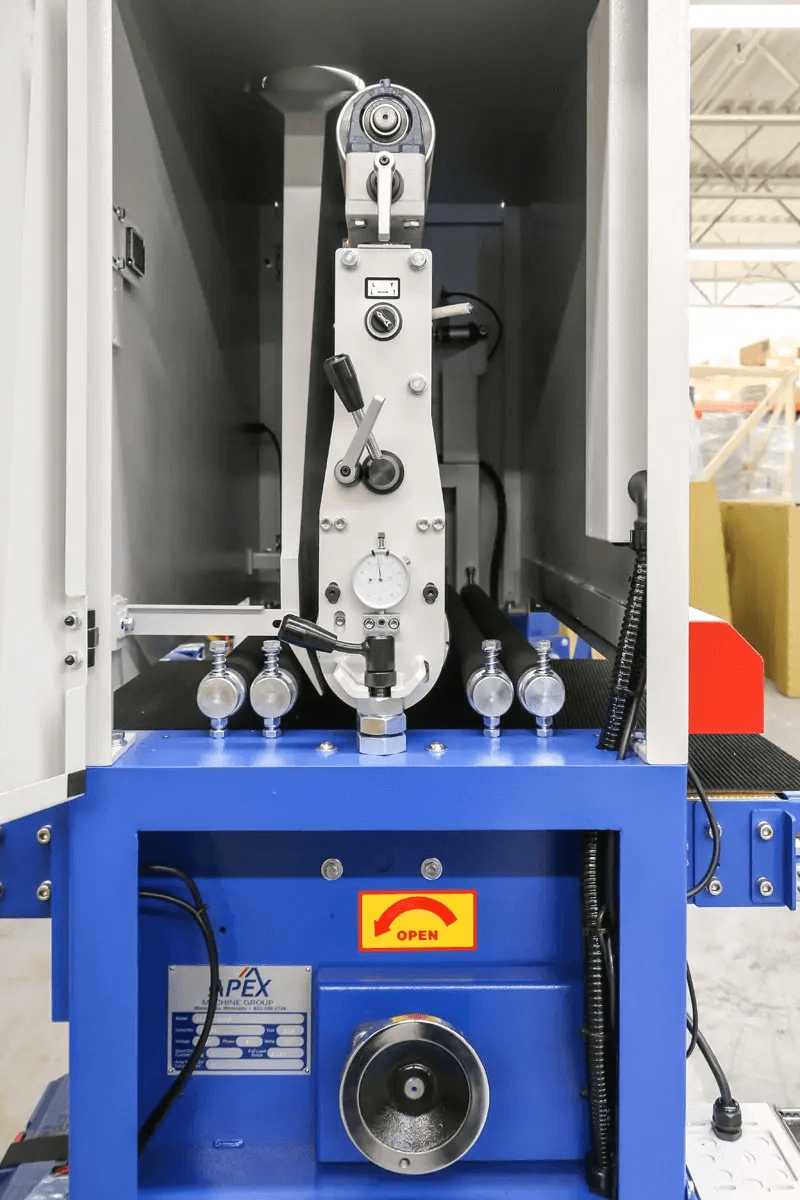

- Electronic abrasive belt tracking

- Pneumatic abrasive tensioning

- Air operated disc brake

- 6″ diameter cam adjustable contact drum with dial indicator

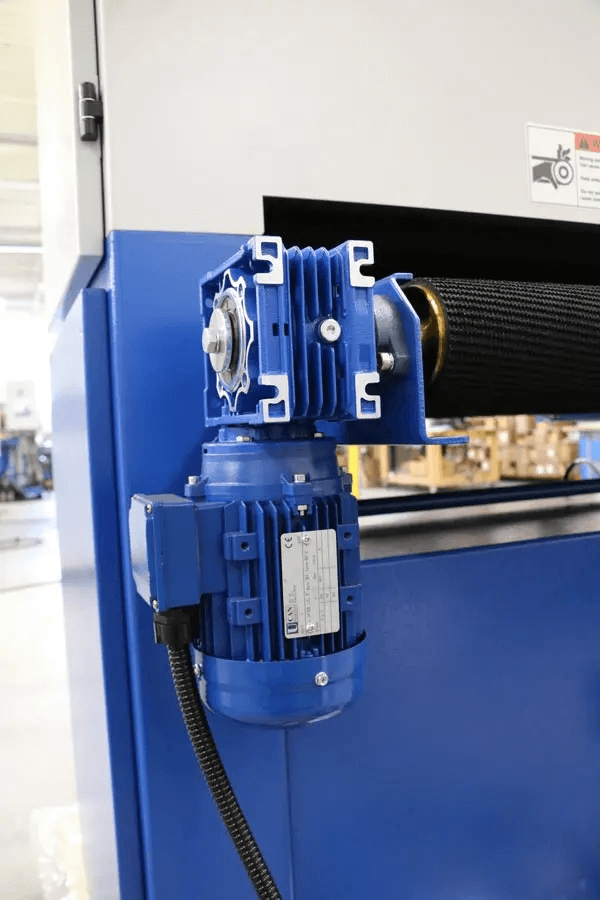

- Heavy-duty welded frame

- Casters for portability

- Optional portable 5 HP wet dust collector

- MODELS

- ACCESSORIES

- EZ SANDER MACHINE SPECIFICATIONS

- PART PROCESSING LIMITATIONS

| Starting at: |

| Starting at: |

| Starting at: |

| Starting at: |