The future of production equipment is here.

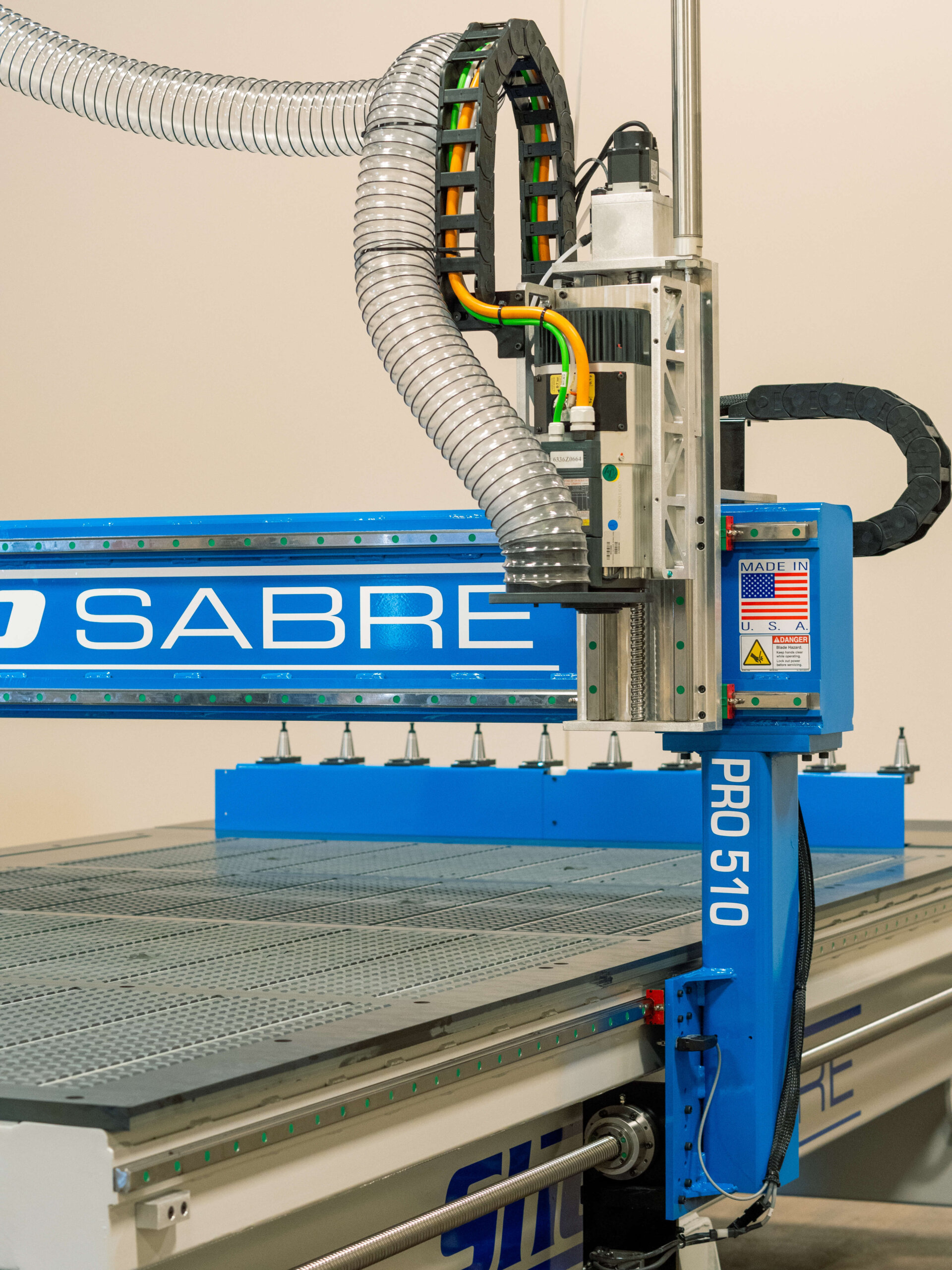

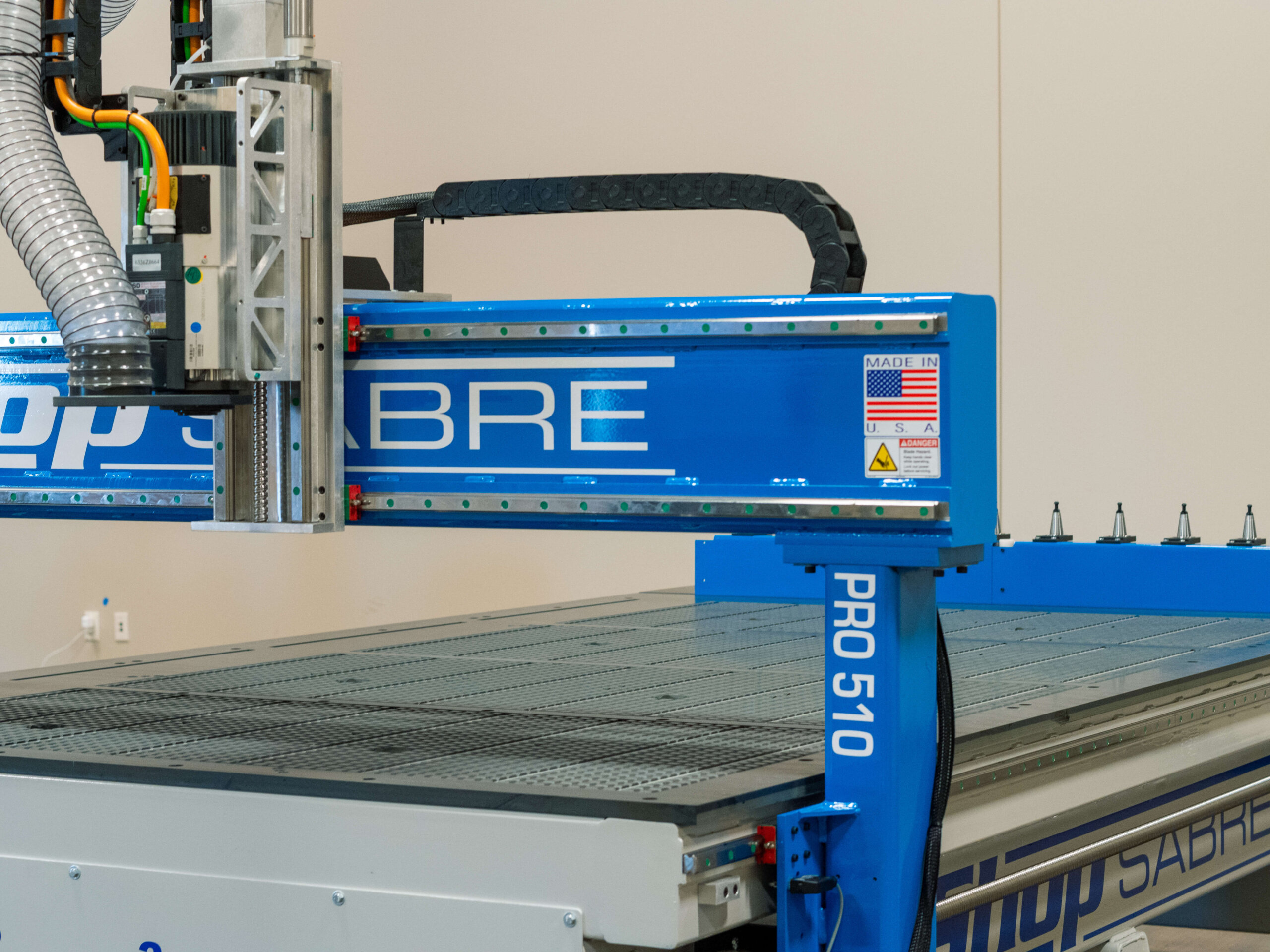

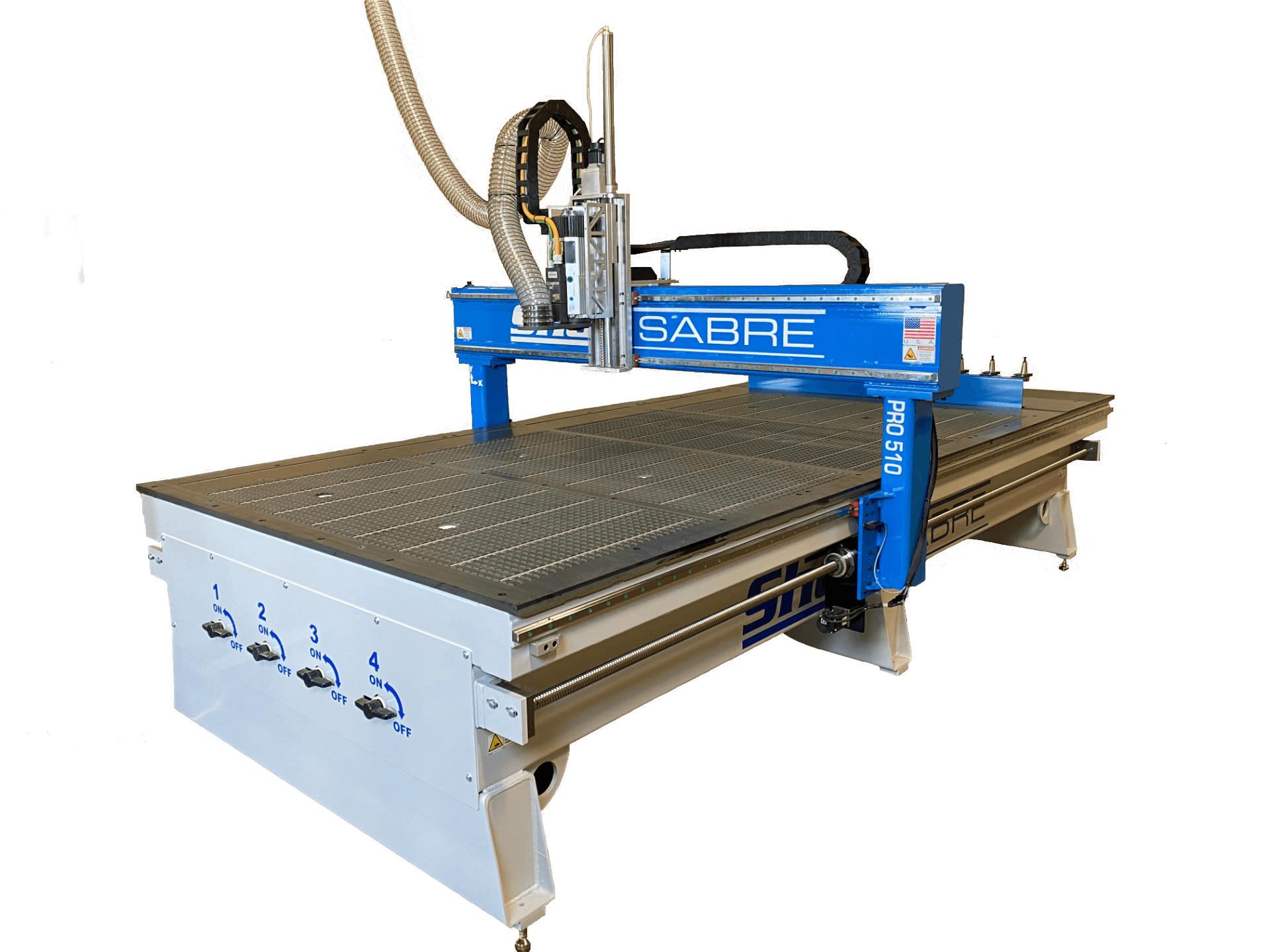

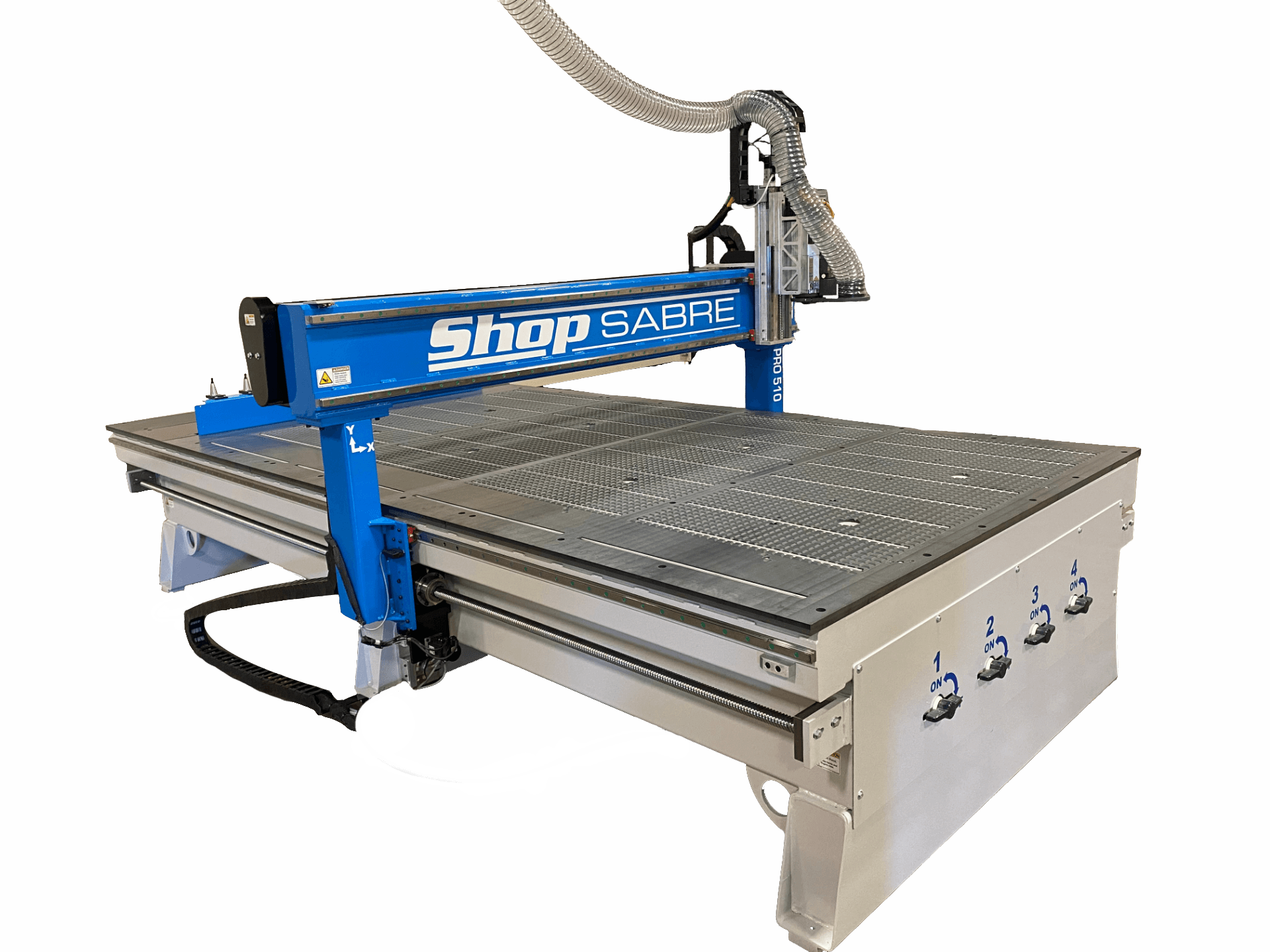

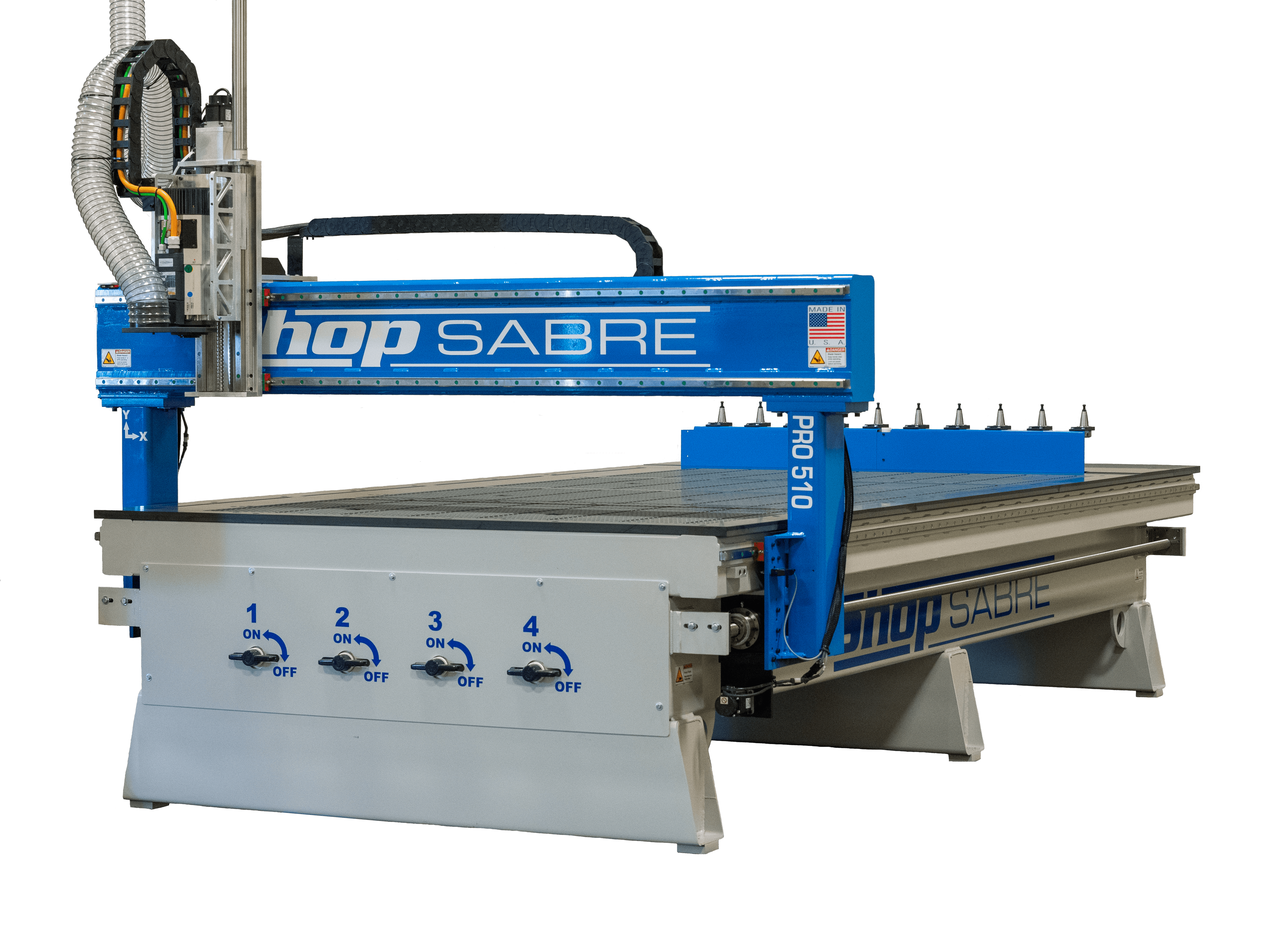

As our most popular CNC router, the PRO Series offers amazing upgrades in technology, durability, and force. Built to outperform every comparably priced machine on the market, the PRO Series is loaded with top-of-the-line components and technology you’d expect to find in machines that cost $80,000 or more. Add in our free lifetime technical support and 100% American made construction, and you simply won’t find a machine that provides more value.

The PRO Series CNC router features over-sized heavy duty structural tube steel frame, gantry, and structural tube steel gantry uprights along with an industrial anti-backlash ball screw drive system on EVERY axis. Designed to produce high quality parts every time whether you are performing nested based sheet work, MDF Doors, one-off custom machining, or anything in between, the PRO Series gives you everything you need for true production. The over-sized working area lets you complete any project on a wide variety of materials including 5 x 5 processing on the 4 x 8 and 5 x 10 systems. Perfect for manufacturing, furniture, cabinets, signs, R&D, and even at-home use, the PRO Series has the capabilities to take your production to the next level.

Contact us today to learn more about the ShopSabre PRO Series CNC routers.

| Starting Manual Change: | $28,400 - $36,400 |

| Finance for as low as | $573/month |

| Starting at with ATC: | $28,400 - |

| Finance for as low as | $706/month |

| Starting at with Manual Change: | $32,900 - $40,900 |

| Finance for as low as | $663/month |

| Starting at with ATC: | $32,900 - |

| Finance for as low as | $796/month |

| Starting at with Manual Change: | $34,900 - $42,900 |

| Finance for as low as | $704/month |

| Starting at with ATC: | $34,900 - |

| Finance for as low as | $837/month |

- PRO 404

- PRO 408

- PRO 510

| Starting Manual Change: | $28,400 - $36,400 |

| Finance for as low as | $573/month |

| Starting at with ATC: | $28,400 - |

| Finance for as low as | $706/month |

| Starting at with Manual Change: | $32,900 - $40,900 |

| Finance for as low as | $663/month |

| Starting at with ATC: | $32,900 - |

| Finance for as low as | $796/month |

| Starting at with Manual Change: | $34,900 - $42,900 |

| Finance for as low as | $704/month |

| Starting at with ATC: | $34,900 - |

| Finance for as low as | $837/month |

- Highlighted Features

- Software

- Uses & Applications

- Materials Cut

- Options

- Relevant Education

- Downloads

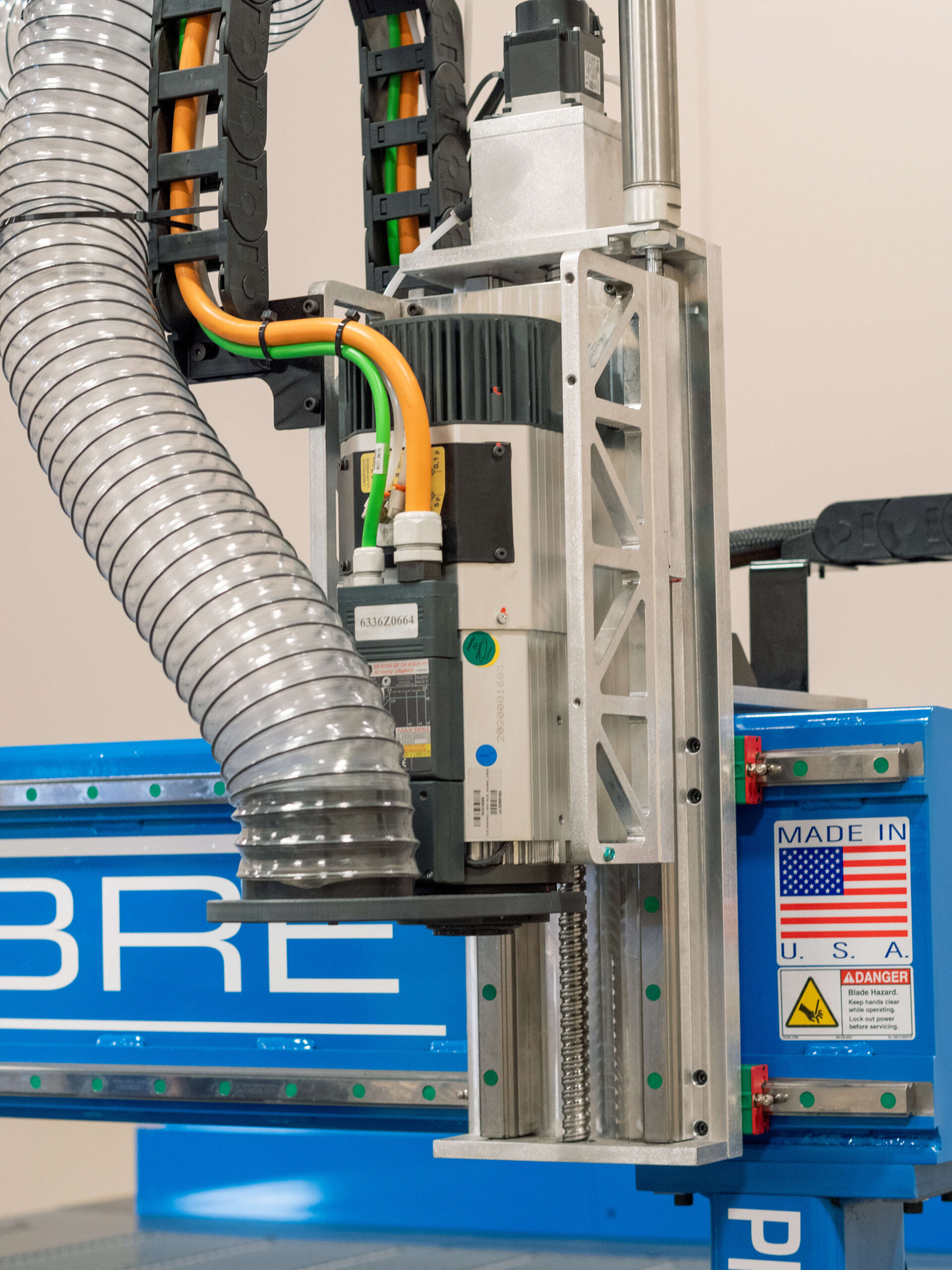

- Italian HSD Electric Fan Cooled Spindle available in 1ph. or 3ph. operation with or without Auto Tool Changer (ATC) Option. (100% Duty Rated)

- Powered 100% by ball screw drive systems with a Dual Driven Y Axis (Long Axis) and our Anti-Whip Technology– Watch our ball screw video!

- Industry Leading Mitsubishi Components including Industrial Digital A/C closed loop brushless servo motors with glass encoder technology and individual drive amplifiers with digital tuning – Watch our top servo motor technology video!

- Industrial Welded, stress-relieved, and Aerospace milled structural steel tube frame construction – Watch Aerospace Milling of Frames

- Industrial structural steel tube gantry uprights and Steel Cross bridge with Milled Mating Surfaces– Watch our steel vs aluminum video!

- High Performance 25MM linear profile guide rails and bearings with Quad Rollers on all axis – Watch Linear Guide Rails

- ShopSabre State-of-the-art Tool Measure Technology – Watch our tool measure video!

- ShopSabre Re-enforced Z Axis Technology with Tool Plate Stiffeners and Optional Super Z Technology!

- Quick Release Dust Skirt Technology (Ask about Dust Dock Technology for ATC Systems) – Watch Dust Dock Videos

- Vectric VCarve PRO CAD/CAM Full License Software

- Easy-to-learn software with point-and-click technology including AT machine CAD/CAM abilities – Watch our control screen video!

- At Machine Solid State Hard Drive for Easy Job Storage and Machine dedicated high speed multi-axis controller Technology

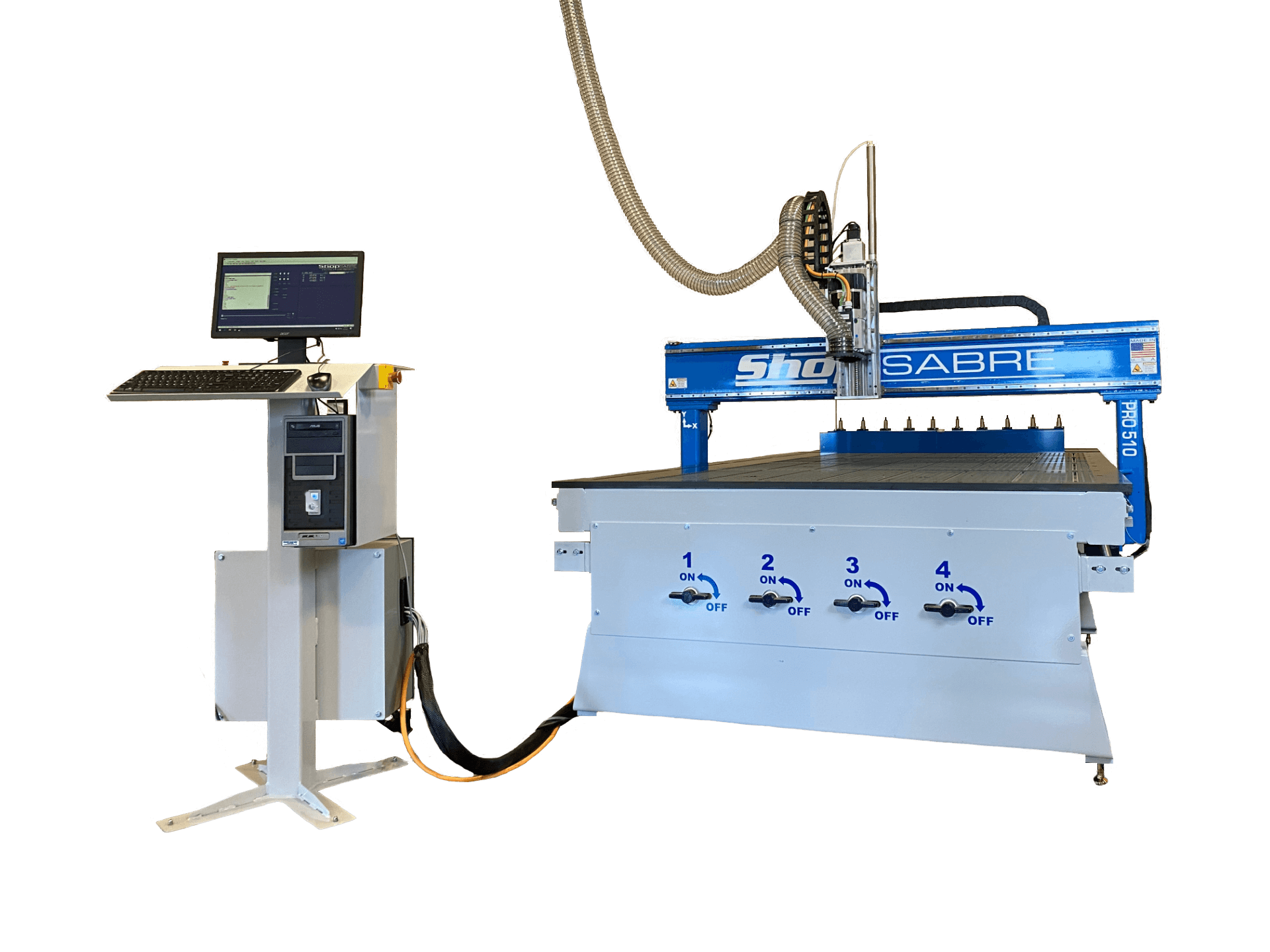

- Machine Operator Control Tower with Auto Leveling Feet and Included PC System with full Networking and file management via USB and internet connectivity

- Free SabreNation Life-Time Tech Support via Phone, Email, and Remote Diagnostic! – Watch our support video!

- Free SabreNation Life-time Training and SabreNation University Access! Get Your CNC Education

- Included Complete Warranty

- Quick and Effortless Installation – Machine Ships Fully Assembled with No Installation Assistance Required!

- MADE IN THE U.S.A. — American Manufactured & Engineered using FEA Software – Watch our engineering video!

- Grow with your business by expanding options that meet your exact needs – Watch our expansion equipment video

- Vectric V-Carve Pro – Features nesting, 2D, 2.5D, 3D CAM capabilities, Vbit carving, sign making, photo importing, 4th axis capabilities, drill cycles, and much more! Watch Video Now

- Drawing to cut file in under 30 seconds

- Easy to learn with included training, tutorials, and support

- Just point and click! Pick cut strategies (Use a large bit to hog out the areas and a small bit to clean up the details

- Easy-to-learn software with point-and-click technology including AT machine CAD/CAM abilities – Watch our control screen video!

- At Machine Solid State Hard Drive for Easy Job Storage and Machine dedicated high-speed multi-axis controller Technology

- Machine Operator Control Tower with Auto Leveling Feet and Included PC System with full Networking and file management via USB and internet connectivity

The PRO Series has unlimited uses and applications, including:

- Prototype manufacturing

- Nested-based manufacturing

- Sign making

- MDF Doors

- Engineering

- R&D/Job shops

- Cabinet/door/closet manufacturing

- Musical instrument manufacturing

- Medium duty to high production

- Solid Surface work

The PRO Series can accurately cut virtually any hard material including:

- Wood

- Acrylic

- Plastic

- Foam

- Aluminum

- Brass

- and More

Available attachments for ShopSabre CNC router models. Please note that some options may not be available on all models or with other options. Some options may result in limiting the cutting/working areas. Contact us for more details

- Manual Change HSD Spindles in 4HP or 9.3HP

- Auto Tool Changer Systems – 5 or 10 Positions with HSD Spindles in 5HP or 10HP

- Phenolic Table Top

- Full Aluminum T-Slot Table Top

- Hybrid T-Slot/Vacuum Table Top (Available with Phenolic Upgrade)

- Hybrid T-Slot/MDF Table Top (Available with Phenolic Upgrade)

- Vacuum Table with 4 Zones and 8 Table Pipes

- FPZ Vacuum Pump

- Becker Vacuum Pump

- ShopSabre F4 Single Phase Vacuum Pump (Ask for Details/Limitations)

- Material Thickness Calibration Touch Pad

- Table Reference Pins (Pop-Up Pins) for Sheet Alignment – Availability dependent on Machine Model

- 2D/3D Parts Digitizing Touch Probe

- On-Table 4th Axis /Rotary Indexing Heads

- Touch Screen Controller

- Multi-Tool System (MTS)– Incorporates Single Cutting Head with Side Mounted Porter Cable Router

- Braille/ADA Sign Attachments/Tooling

- Vision Systems for Registration Mark Reading from Flat Bed Printer

- Tangential Oscillating Knife System

- Dust Collector Options

- Wireless Hand Control Pendant with Jog Wheel

- Multiple Cutting Head Attachments (2 or More Cutting Heads – May Reduce Working Area)

- Nesting, Cabinet, 3D, 2D, and Photo Recognition Software Packages

- Laser Sight for Quick Zero Reference

- Safety Mats & Light Curtains

- Warning Light Bar

- Private 1 on 1 Training (On-Site and In House)

- Vacuum Pods

- JTech Entry Level Marking Laser Options

- Dust Dock ATC Containment Dust Skirt with Dock

- Dust Dock Manual Change Containment Dust Skirt

- Vortex Tooling Packages

- Mist System for Aluminum Cutting

- Air Blower for Plastic Cutting

- UL/CUL by Request