Industrial Small CNC Plasma Cutter at Entry Level Cost!

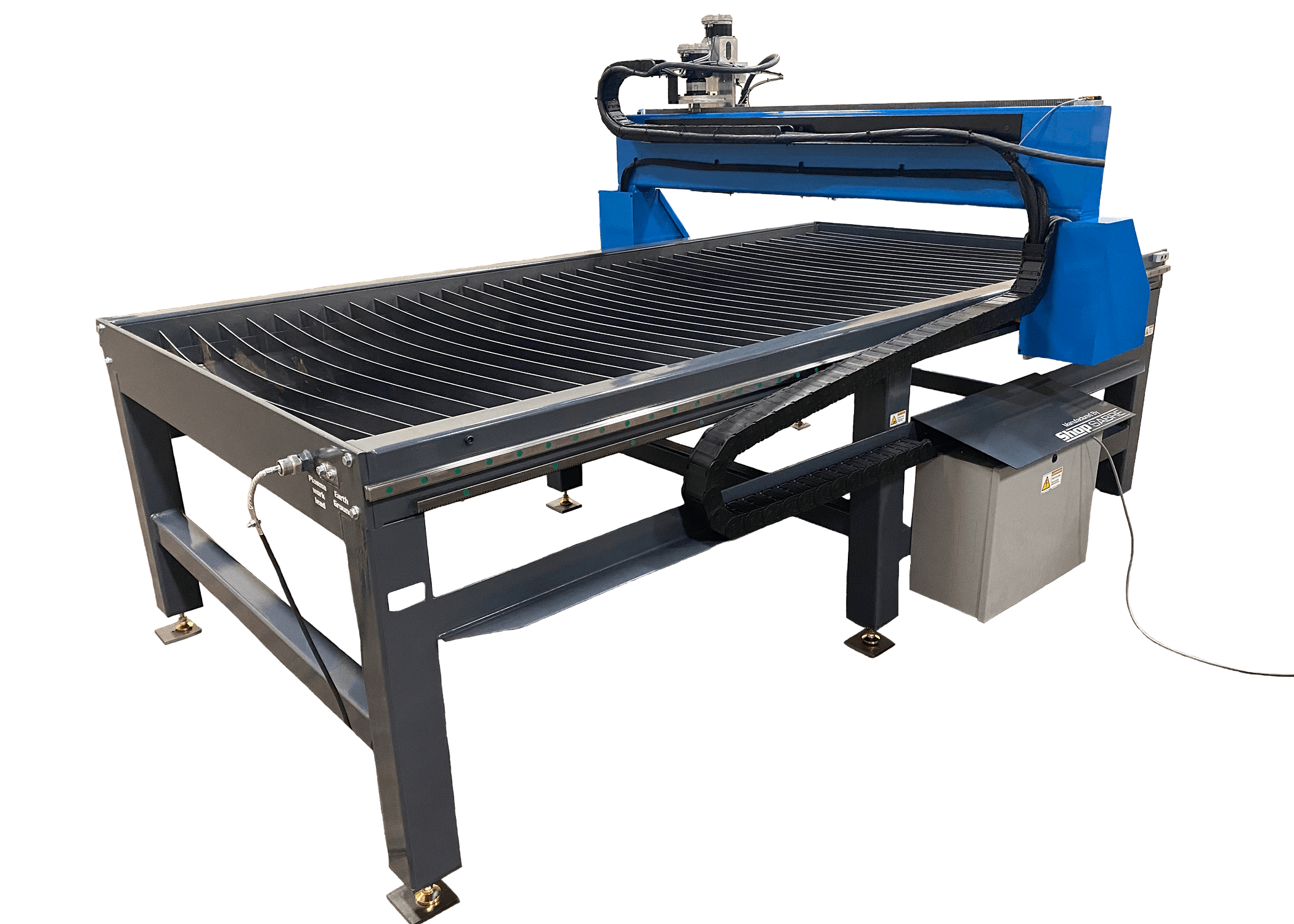

Every fabricator needs a SideKick, the ShopSabre SideKick CNC Plasma Series is designed to give you an edge over your competition. Entry level priced but Industrial designed, the ShopSabre SideKick Series brings technology that normally costs you $60,000 to a price you CAN afford! Whether your shop needs to run the CNC Plasma for 1-2 hours a week or 8+ hours every day the ShopSabre SideKick is built to perform!

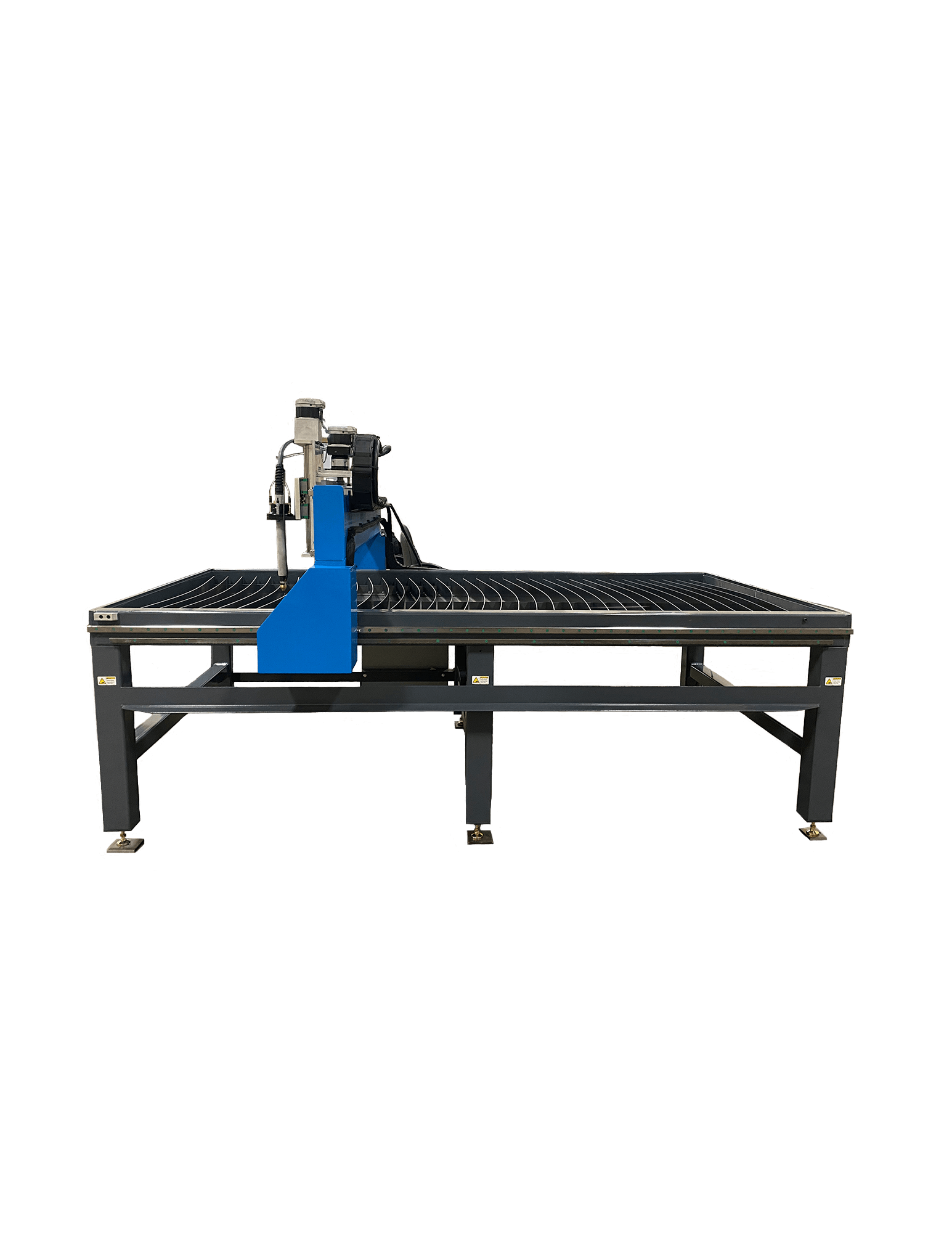

The SideKick Series is specifically FEA engineered, designed, and manufactured here in the U.S.A. Constructed of the heaviest Frame in the Light Industrial Class made from Large Structural Tubes welded together as a one piece frame paired with our industry famous Industrial Structural Tube Steel Gantry the machine Frame is built to handle the cutting forces of routing and heat tolerances of plasma continuously outperforming the competition. Every ShopSabre SideKick Series comes standard with High Torque North American Servo Motors on X, Dual Y, and Z Axis paired with Direct Drive Planetary Gears for higher accuracy, less maintenance, and more power!

Loaded with the same high-end electronic components you’ll find on much larger industrial machines, the SideKick series gives you more capabilities without taking up more of your budget. Perfect for manufacturing plants, automotive shops, fabricators, schools, and many other settings, the SideKick series requires no assembly and can be put to work within minutes of its arrival to your shop!

Need plasma and routing abilities in the same machine? The SideKick is the most advanced and capable combination table on the market by simply adding one of our CNC Router packages! You’ll be able to perform metal plasma cutting and wood routing with ease whether you are a hobbyist or a full production shop.

Contact us today to learn more about the ShopSabre SideKick Series CNC plasma.

| Starting at: | $15,495 - $18,495 |

| Finance for as low as | $312/month |

| Starting at: | $16,995 - $19,995 |

| Finance for as low as | $343/month |

| Starting at: | $18,495 - $21,495 |

| Finance for as low as | $373/month |

| Starting at: | $20,995 - $23,995 |

| Finance for as low as | $423/month |

- SideKick 4

- SideKick 8

- SideKick 10

- SideKick 12

| Starting at: | $15,495 - $18,495 |

| Finance for as low as | $312/month |

| Starting at: | $16,995 - $19,995 |

| Finance for as low as | $343/month |

| Starting at: | $18,495 - $21,495 |

| Finance for as low as | $373/month |

| Starting at: | $20,995 - $23,995 |

| Finance for as low as | $423/month |

- Highlighted Features

- Software & Controller

- Uses & Applications

- Materials Cut

- Options

- Relevant Education

- Downloads

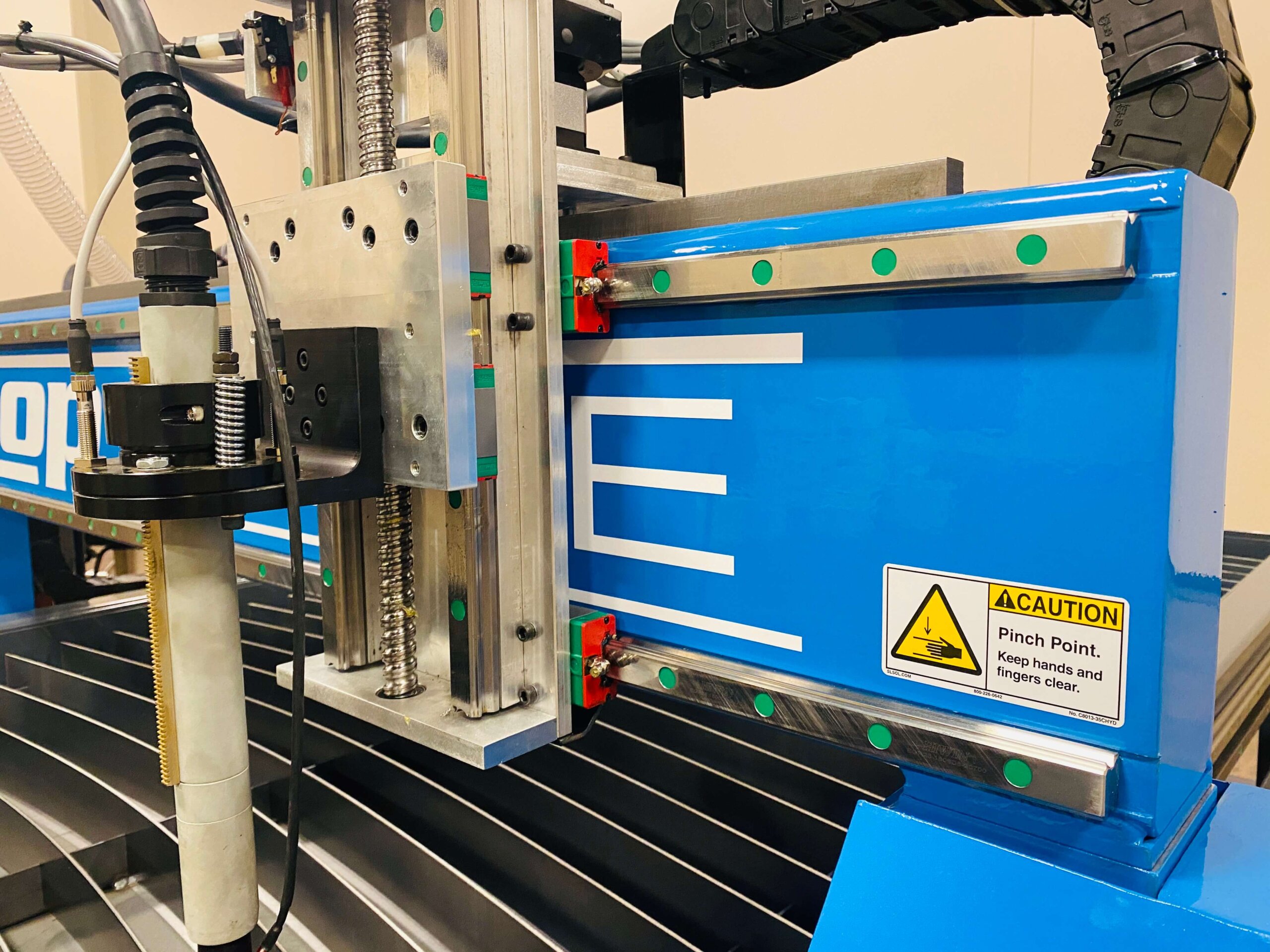

- Dual Driven Y Axis (Long Axis)

- Powered 100% by High Torque Industrial Closed Loop brushless servo motors with encoder technology

- Direct Drive Planetary Gear Reduction XY Axis

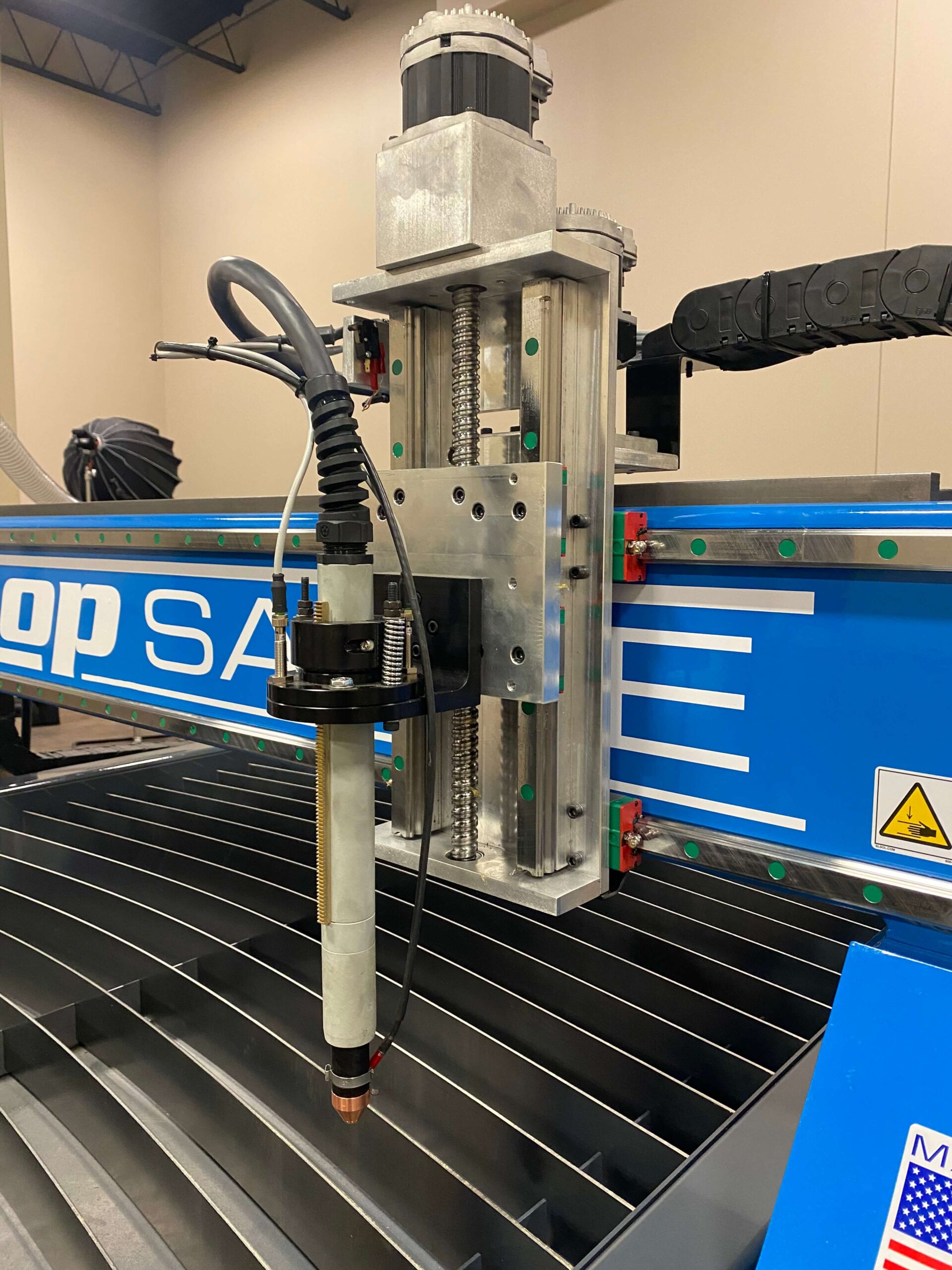

- Advanced Direct Drive Ball Screw Z Axis

- Industrial Welded, stress-relieved, and Aerospace milled structural steel tube gantry construction with 8” Gantry Clearance – Watch our steel vs aluminum video!

- Industrial structural steel tube welded 6 Leg Frame with steel tube cross bracing for added stabilization and increased rigidity. No Extruded Aluminum or Low-Cost Bolt together Designs – No assembly required

- High Performance 25MM linear profile guide rails and bearings with Quad Rollers on all axis

- ShopSabre exclusive low maintenance “Floating Drive Technology” for Improved XY Motion with Inverted Rack and Pinion to reduce maintenance and increase torque.

- Breakaway Torch Mount with Built in Level for Easy Torch Alignment

- Integrated Advanced Digital Torch Height Control with Ohmic Touch System (Ask for Details)

- Integrated Touch Distance Control

- Industrial Continuous Flex Robotic Wiring with Enclosed Wire Carriers for Wiring Protection and noise Isolation.

- Complete Set of Table Slats with Slat Brackets Installed from Factory (Blow through design standard – Water Table or Down-Draft Optionally Available)

- 12 Month Subscription for Hypertherm ProNest LT Unlimited & EnRoute Fabrication 7 – Features Nesting, 2D CAD/CAM, Shapes Library, Sign Making, Photo Importing, Lead Ins & Outs, & more! Hypertherm ProNest LT Unlimited. Enroute Fabrication 7.

- Easy-to-learn software with point-and-click technology including AT machine CAD/CAM abilities – Watch our plasma control screen video!

- Integrated Plasma Cut Chart with Pre-Configured Material Library

- At Machine Solid State Hard Drive for Easy Job Storage and Machine dedicated high speed multi-axis controller Technology

- Includes Tracing Technology as seen on Powerblock TV – Watch our search and restore video!

- Machine Operator Control System with Monitor, Keyboard, and Mouse. Includes Windows OS with full Networking and file management via USB and internet connectivity

- Free SabreNation Life-Time Tech Support via Phone, Email, and Remote Diagnostic! – Watch our support video!

- Free SabreNation Life-time Training and SabreNation University Access!

- Included Complete Warranty

- Quick and Effortless Installation – Machine Ships Fully Assembled with No Installation Assistance Required!

- MADE IN THE U.S.A. — American Manufactured & Engineered using FEA Software – Watch our engineering video!

- Optional Router Accessories Available for Routing needs – Insert Combo Machine Video

- Grow with your business by expanding options that meet your exact needs – Watch our expansion equipment video

- 1 Year of Hypertherm ProNest LT Unlimited – Features Nesting, 2D CAD/CAM, Shapes Library, Sign Making, Photo Importing, Ongoing Training & Support, and much more! Watch Video Now

- Drawing to cut file in under 30 seconds

- Easy to learn with included training, tutorials, and support

- Just point and click! Pick cut strategies (Kerf Compensation, Lead In, Lead Out)

- Easy-to-learn software with point-and-click technology including AT machine CAD/CAM abilities – Watch our control screen video!

- At Machine Solid State Hard Drive for Easy Job Storage and Machine dedicated high-speed multi-axis controller Technology

- Included PC System with full Networking and file management via USB and internet connectivity

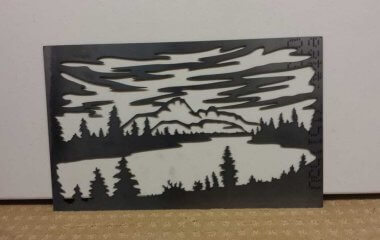

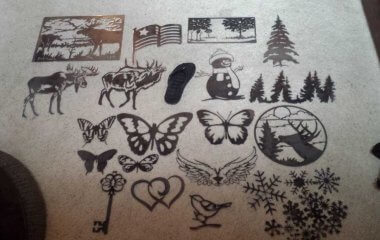

The SideKick Series has unlimited uses and applications, including:

- Prototype manufacturing

- Nested-based manufacturing

- Sign making

- Engineering

- R&D/Job shops

- Entry Level to Medium Production

- Automotive

The SideKick Series can accurately cut virtually any hard material including:

- Aluminum

- Steel

- Stainless

- Copper

- Brass

- and More

* Appropriate Safety Measures Recommended for Operators Safety*

Available attachments for ShopSabre CNC plasma models. Please note that some options may not be available on all models or with other options. Some options may result in limiting the cutting/working areas. Contact us for more details.

- On-Table 4th Axis /Rotary Indexing Heads for Pipe & Tube

- SideCar 4th Axis /Rotary Indexing Heads for Pipe & Tube

- Control Centers & Enclosed Computer Cabinets

- CNC router Upgrade for Plastic and Wood Cutting

- Parts Digitizing Probe

- Sheet Alignment Brackets

- Down-Draft Single or Zoned Tables

- Water Tables (Manual)

- CNC router Upgrade Table Top for Clamping Wood/Plastic Materials

- Touch Screen Industrial Machine Mounted Element Controller

- Hand Control Pendant

- Routing, Nesting, 3D, and Photo Recognition Software Packages

- Plate Marking Scribe

- Cutter Options (Thermal Dynamics & Hypertherm)

- Oxy/Fuel Attachments

- Torch Alignment Laser Sights

- Torch Collision Detection

- Defense Water Treatment

- Safety Mats & Light Curtains

- Running Warning Lights

- Training (On-Site and In House)

- Marker Pen Attachment

- Water Table Splash Guards

- Water Table Bubbler for use with Aluminum Cutting

- Secondary Drill Head for Drilling Holes