CNC plasma: Water table vs. Downdraft table

By scribe

In CNC work, dust and fume control and ventilation are critically important in the shop, not just for the health and safety of everyone involved but for the long-term condition and performance of your equipment, as well.

Without proper dust collection and ventilation, health issues can arise over time and the quality of your work is guaranteed to take a significant hit. Because of this, you need to make sure your ventilation system and processes are properly set up and that any accessories like ShopSabre’s Dust Dock for CNC routing are utilized wherever needed.

In addition to these methods, leveraging a water table or downdraft table can also prove effective in limiting the presence of dust, fumes, and smoke anytime you’re operating a CNC plasma machine. Here is a closer look at the key differences between a water table and a downdraft table along with the primary advantages and disadvantages of each.

What is a water table?

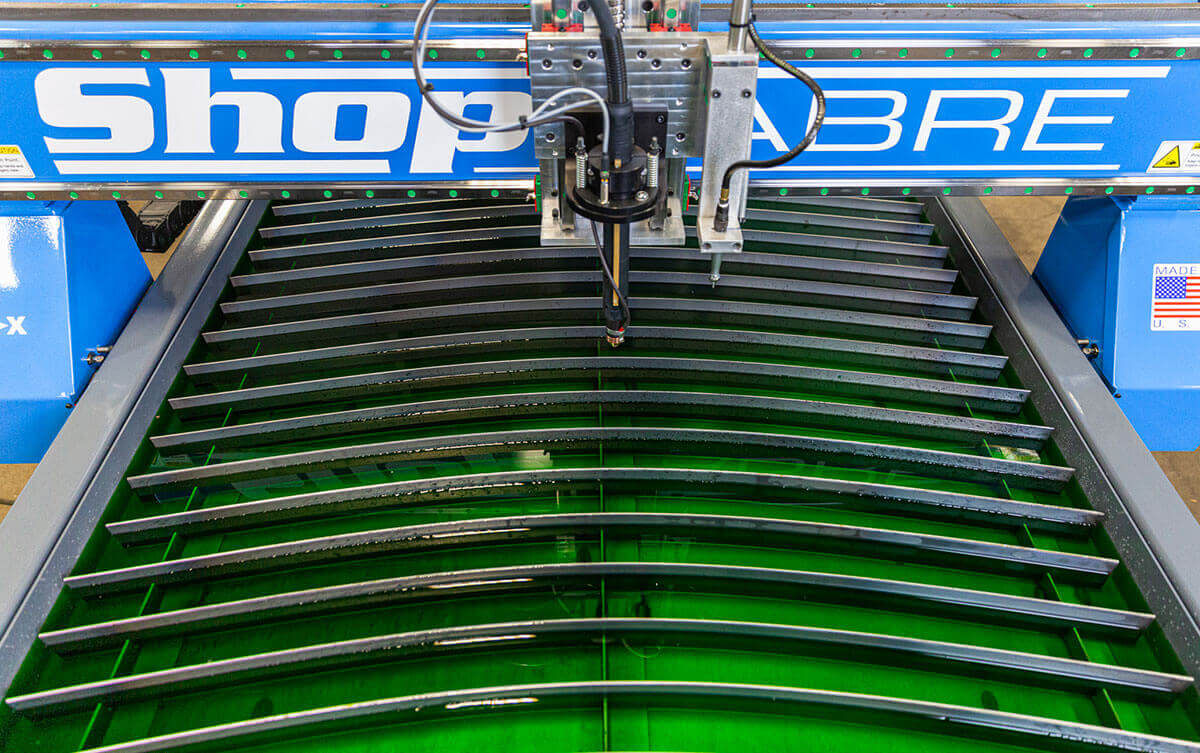

A water table consists of a water tank typically ranging from 2-24 inches in depth that sits beneath the cutting surface of your CNC plasma machine. The cut material rests on vertical metal bars known as slats during cutting, where the water level typically rises to somewhere between .125 and .25 inches below the bottom of the workpiece. Some operators with appropriate cutters may even fully submerge the plate and plasma torch beneath the water during cutting.

As cuts are executed, the cutting force pushes the debris and smoke beneath the surface and into the water beneath the material. This traps fume and smoke particles while cooling the debris (slag) that sinks into the water. The water also reduces the heat level of the cut and of the material, which can reduce warpage and ensures parts cool more quickly and can be safely removed and used immediately after cutting.

Water table advantages

- Improved fume control often reduces dust and smoke by 90-95%

- Reduced plate warpage as water cools the material

- Reduced upfront costs due to reduction in needs for fans, filter, or external power costs

- Reduced noise due to lack of fans

- Ready-to-use parts and reduced slag

Water table disadvantages

- Risk of water splashing and potential for leaks (ShopSabre’s splash guards can help, and all of our water tables are leak-tested prior to shipping)

- Drying of parts may be required

- Water treatment is required to prevent corrosion

What is a downdraft table?

With a downdraft table, air from a fan, blower, or suction system flows down through the table and pulls dust and fumes away from the underside of the cutting area and out of the shop through an HVAC, filtration, or duct system. Downdraft tables have a bit higher upfront cost than water tables and do require more additional equipment, but they also typically are a cleaner system to maintain due to the absence of water.

Downdraft table advantages

- Improved fume control often reduces dust and smoke by 70-90% (fume reduction will vary based on the quality of the fan/pump system installed)

- No need to check or adjust water levels

- Dust and particles can be neatly collected for quick and easy disposal

- Minimal maintenance required for the table (fume systems have their own maintenance)

- No need to worry about leaking or splashing

Downdraft table disadvantages

- Higher upfront cost due to HVAC installation costs

- Additional equipment required (fans, dust collection equipment, etc.)

- Higher power usage due to needing to run a fan/pump

- Increased risk of warpage due to increased heat

- More time required for parts to cool before handling or using

- Added regulations due to air pollution regulations (see your local regulations)

- Less smoke collection on nested large area parts (air travels to the area of least resistance)

Achieve optimal air quality in your shop with ShopSabre

ShopSabre’s industry-best CNC routers and plasmas are designed to help shop owners grow their production through unmatched precision, repeatability, and automation – all at an affordable price.

Our machines are easy to get up and running and to learn how to operate, even without any formal training. Our team of dedicated experts offers one-on-one support to help find the right machine for you and to make sure it works the way you and your business need it to.

Here are a few of the reasons ShopSabre is able to develop and produce such revolutionary CNC technology:

- Experienced in-house engineering talent

- The ability to totally fabricate and test designs onsite

- The ability to place the designs into production in-house

Shop our unmatched collection of CNC routers and CNC plasmas in Minneapolis today to experience CNC the way it was meant to be.